products categories

contact us

- If you have questions, please contact us, all questions will be answered

- Tel : 18030236818

- Fax : +86-592 5237901

- Email : dexing@china-dexing.com

Multi-dimensional magnetic field system

It can test the whole magnetic field three-dimensional distribution of the stator and rotor of permanent magnet motor, AC motor, micro motor, etc., and test the three-dimensional magnetic field values of different points at different levels of each angle. so as to fully understand the overall distribution of the internal magnetic field of the motor and the magnetic leakage outside the motor.

contact nowMulti-dimensional magnetic field system

Characteristic

1. Wide range of measurement:Space measure range is 200mm x 200mm x 200mm (X,Y,Z)(it can be customized, please advise if there's special requirement), free tour optional three directions, and will reached 5Axis platform when rational platform attached to it. Translation meticulous(Resolution ratio: 0.00039mm),Positional accuracy 0.01mm,Repeat positional accuracy<0.005mm, Rotation travel angle resolution ratio <0.0002°, positional accuracy 0.01, Repeat positional accuracy <0.005°,Velocity of movement can be divided into 2-64 classes. Fine distribution of measure space on the physical space.

2. High accuracy of system measurement: Using high-precision digital Gauss meter (one-dimensional or multi-dimensional) equipped with micro Hall probes (one dimensional ɸ0.5mm,two-dimensional ɸ1.2mm,three-dimensional ɸ1.2mm)make space and surface magnetic measurement up to higher accuracy.(One-dimensional precision can up to ± 0.05% of reading, range±0.005.Three-dimensional precision can up to ± 0.10% of reading, range ± 0.005 )

3. Automation and Digitization: The real-time control and data acquisition controlled by computer, system software design measure processes that can be divided into many forms, user can directly enter data parameters of the measured object for fully automated measurement, data is automatically recorded and saved, based on test data system can generate one dimensional, two-dimensional, three-dimensional graphics and measurement data logging, database format is Access and print the chart.

4. Flexible combinations: Three-dimensional translation platform and rotation platform can be assembled in many suitable situation for various measure methods to meet the needs of the different measurement, system software covers control and data acquisition ,and software function can also be extended as required, realizing full automation of unmanned monitoring measurement.

5. Gauss meter tested by National Institute of Metrology,China; System software registered and approved by CPCC(Copyright Protection Center of China)

System configuration

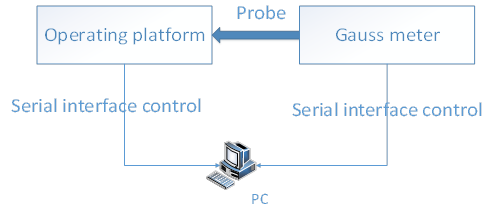

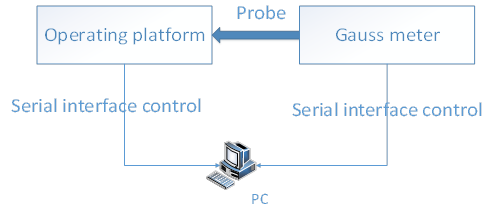

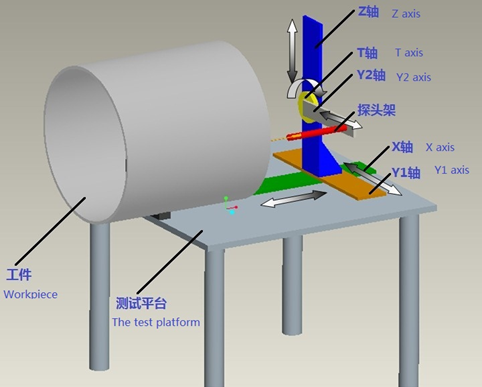

The system consists of PC (equipped with control software), high-precision gauss meter (one-dimensional or three-dimensional), the probe that agree with gauss meter, displacement multidimensional electronic control units as well as the displacement station controller. As shown in the schematic picture above, the system can be simply divided into two parts, one is used to collect the data, and the other part is only displacement, the two parts make up the acquisition system.

The displacement part consist of electronic control displacement module and displacement station controller, by operating the PC software to send command to controller, the controller will drive the electric displacement units control each axis motion according to the command, the parameters of this electronically controlled displacement table can be customized by users (table size, the length axis of motion, movement, the number of dimensions) ,realizing scan of various angles and various shapes within the allowable range.

High-precision data acquisition module consists of Gauss meter and probe agree with Gauss meter, axis motorized translation table has a fixed position of the probe holder, the probe is placed in the holding position when collecting data, real-time measurement of the probe data upload to the Gauss meter, while Gauss meter connected PC software to communicate with the host computer then choose whether to record the data of the current location as needed.

PC software controls the displacement station controllers and Gauss meter, the position of the table is associated to gauss meter read data values, the one-dimensional Gauss meter reading is the magnetic data values on current position in a direction corresponding to the point, three-dimensional Gauss meter reading is value in the X direction, the value of the Y-direction, the value of the Z direction at current point, and the temperature on this point (as needed probe and gauss meter may be equipped temperature compensation function) and in two triaxle numerical size and direction of both vector sum and total vector sum and angle, the scanned data can be exported in Excel and be mapped out the various needs of the diagram by the position and the data value, such as the standard two-dimensional drawing, a two-dimensional drawing, two-dimensional reverse drawing, two-dimensional radar, three-dimensional network diagram, three-dimensional drawing, vector, cylindrical expansion plan and multiple curves or more three-dimensional map for comparison on the same graph. Software also integrate several common shapes (spatial field distribution, rectangle, concentric circle, etc.), just set a few parameters can be automatically scanned, high degree of freedom, high accuracy and unsupervised, Specific circumstances can refer to the following graphic in Part 3 System software.

CNC Multi Axis Platform

(X ﹑Y﹑Z﹑T、θz)

Axis can be selected, panning trips and rotating table diameter can be selected

Direction | Panning trips | Resolution |

X | 50mm-4000mm | 0.00039mm |

Y | 50mm-2000mm | 0.00039mm |

Z | 50mm-2000mm | 0.00039mm |

T(Rotary table) | 360° | 0.0002º |

θz(Rotary table) | 360° | 0.0002º |

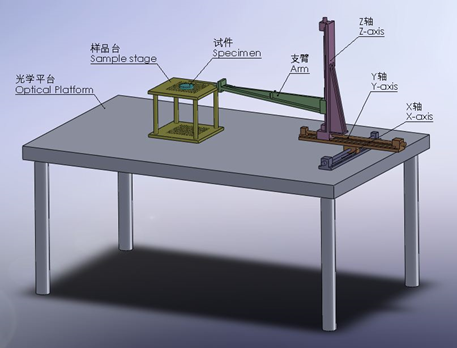

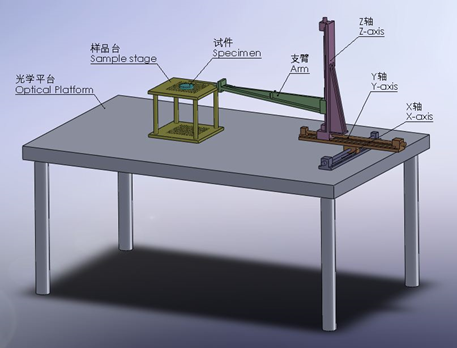

Composite Structures 1:(Specific types of applications in following)

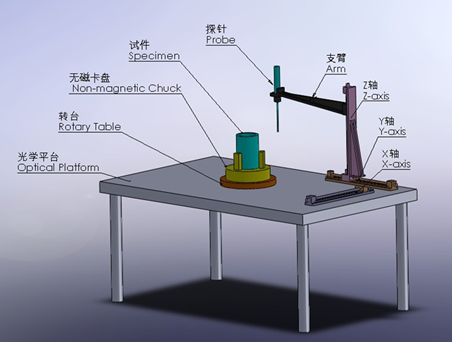

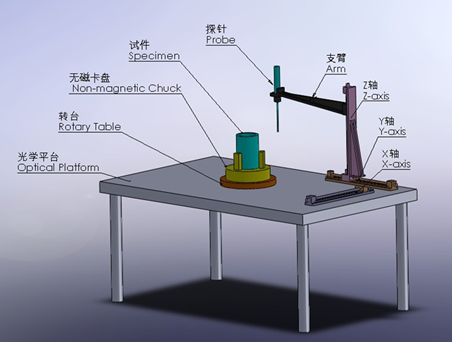

Composite Structures 2: (Specific types of applications in following)

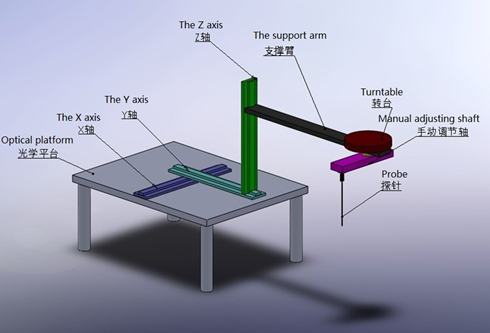

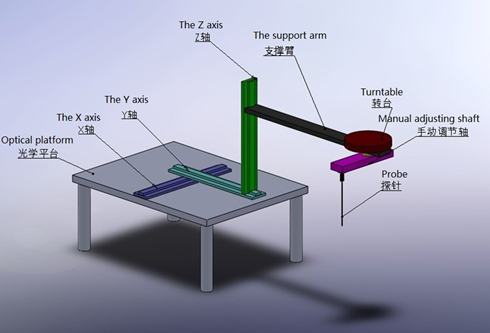

Composite Structures 3: (Specific types of applications in following)

Multi-dimensional magnetic field testing system

It can test the whole magnetic field three-dimensional distribution of the stator and rotor of permanent magnet motor, AC motor, micro motor, etc., and test the three-dimensional magnetic field values of different points at different levels of each angle. so as to fully understand the overall distribution of the internal magnetic field of the motor and the magnetic leakage outside the motor.

Overview

Multi-dimensional high precision digital magnetic measuring system developed by our company is magnetic measure platform of high-precision and digitation and automation that has the highest international level, it insists of high-precision numerical control micro-platform and multi-dimensional high-precision digital gauss meter and control acquisition software, It can measure the magnetic field characteristic of high precision, such as the distribution of magnetic field, magnet surface and three-dimension, and the distribution of uniformity, magnetic loop and N/S magnetic pole, motor magnetic, superconducting magnetic field, magnetic resonance magnetic field and so on, then it can draw all kinds of graphics, save data, preserve and print them out. The system applies to all kinds of magnetic research, and it is of immense importance in terms of the analysis of the high- precision magnetic field, which has been widely used by numerous domestic and international aerospace, military industry, scientific research and colleges.

Characteristic

1. Wide range of measurement:Space measure range is 200mm x 200mm x 200mm (X,Y,Z)(it can be customized, please advise if there's special requirement), free tour optional three directions, and will reached 5Axis platform when rational platform attached to it. Translation meticulous(Resolution ratio: 0.00039mm),Positional accuracy 0.01mm,Repeat positional accuracy<0.005mm, Rotation travel angle resolution ratio <0.0002°, positional accuracy 0.01, Repeat positional accuracy <0.005°,Velocity of movement can be divided into 2-64 classes. Fine distribution of measure space on the physical space.

2. High accuracy of system measurement: Using high-precision digital Gauss meter (one-dimensional or multi-dimensional) equipped with micro Hall probes (one dimensional ɸ0.5mm,two-dimensional ɸ1.2mm,three-dimensional ɸ1.2mm)make space and surface magnetic measurement up to higher accuracy.(One-dimensional precision can up to ± 0.05% of reading, range±0.005.Three-dimensional precision can up to ± 0.10% of reading, range ± 0.005 )

3. Automation and Digitization: The real-time control and data acquisition controlled by computer, system software design measure processes that can be divided into many forms, user can directly enter data parameters of the measured object for fully automated measurement, data is automatically recorded and saved, based on test data system can generate one dimensional, two-dimensional, three-dimensional graphics and measurement data logging, database format is Access and print the chart.

4. Flexible combinations: Three-dimensional translation platform and rotation platform can be assembled in many suitable situation for various measure methods to meet the needs of the different measurement, system software covers control and data acquisition ,and software function can also be extended as required, realizing full automation of unmanned monitoring measurement.

5. Gauss meter tested by National Institute of Metrology,China; System software registered and approved by CPCC(Copyright Protection Center of China)

System configuration

The system consists of PC (equipped with control software), high-precision gauss meter (one-dimensional or three-dimensional), the probe that agree with gauss meter, displacement multidimensional electronic control units as well as the displacement station controller. As shown in the schematic picture above, the system can be simply divided into two parts, one is used to collect the data, and the other part is only displacement, the two parts make up the acquisition system.

The displacement part consist of electronic control displacement module and displacement station controller, by operating the PC software to send command to controller, the controller will drive the electric displacement units control each axis motion according to the command, the parameters of this electronically controlled displacement table can be customized by users (table size, the length axis of motion, movement, the number of dimensions) ,realizing scan of various angles and various shapes within the allowable range.

High-precision data acquisition module consists of Gauss meter and probe agree with Gauss meter, axis motorized translation table has a fixed position of the probe holder, the probe is placed in the holding position when collecting data, real-time measurement of the probe data upload to the Gauss meter, while Gauss meter connected PC software to communicate with the host computer then choose whether to record the data of the current location as needed.

PC software controls the displacement station controllers and Gauss meter, the position of the table is associated to gauss meter read data values, the one-dimensional Gauss meter reading is the magnetic data values on current position in a direction corresponding to the point, three-dimensional Gauss meter reading is value in the X direction, the value of the Y-direction, the value of the Z direction at current point, and the temperature on this point (as needed probe and gauss meter may be equipped temperature compensation function) and in two triaxle numerical size and direction of both vector sum and total vector sum and angle, the scanned data can be exported in Excel and be mapped out the various needs of the diagram by the position and the data value, such as the standard two-dimensional drawing, a two-dimensional drawing, two-dimensional reverse drawing, two-dimensional radar, three-dimensional network diagram, three-dimensional drawing, vector, cylindrical expansion plan and multiple curves or more three-dimensional map for comparison on the same graph. Software also integrate several common shapes (spatial field distribution, rectangle, concentric circle, etc.), just set a few parameters can be automatically scanned, high degree of freedom, high accuracy and unsupervised, Specific circumstances can refer to the following graphic in Part 3 System software.

CNC Multi Axis Platform

(X ﹑Y﹑Z﹑T、θz)

Axis can be selected, panning trips and rotating table diameter can be selected

Direction | Panning trips | Resolution |

X | 50mm-4000mm | 0.00039mm |

Y | 50mm-2000mm | 0.00039mm |

Z | 50mm-2000mm | 0.00039mm |

T(Rotary table) | 360° | 0.0002º |

θz(Rotary table) | 360° | 0.0002º |

Composite Structures 1:(Specific types of applications in following)

Composite Structures 2: (Specific types of applications in following)

Composite Structures 3: (Specific types of applications in following)

Composite Structures 4: (Specific types of applications in following)

Practical Effect Diagram of Composite Structures

inquiry now

We will give you a quotation within 24 hours.

-

DX-2012HC Soft Magnetic Material Coercivity Measuring Device

DX-2012HC Soft Magnetic Material Coercivity Measuring Device

DX 2012HC soft magnetic material coercivity measuring device is mainly used for rapid measurement of soft materials including: pure iron and carbon steel, soft ferrite, magnetic powder and other regular and irregular open circuit samples, and the test method is reliable.

-

DX-100 Hall Effect Measurement System

DX-100 Hall Effect Measurement System

DX 100 Hall effect test system can be divided into normal temperature, high temperature, low temperature, high and low temperature Hall effect test system; It is used to measure the carrier concentration, mobility, resistivity, Hall coefficient, etc. of semiconductor materials; It is an essential tool for studying the electrical properties of semiconductor materials.

-

DX-9000 Series Vibration Sample Magnetometer

DX-9000 Series Vibration Sample Magnetometer

DX-9000 series vibrating sample magnetometer is a kind of magnetometer developed by Xiamen Dexing Magnet Tech. Co., Ltd. The main research and development of the magnetic material measurement system is a new generation of products based on the electromagnet platform.

-

DX-2100AM Magnetization Angle Measurement System

DX-2100AM Magnetization Angle Measurement System

The DX 2100AM magnetization angle measurement system is connected to the independent three component fluxmeter by a three dimensional Helmholtz coil to form a hardware test part;Through a microcomputer conversion of the test data of three components, a complete magnetization angle measurement system is formed.